Hartley News Online Your alumni and supporter magazine

Increased environmental concerns and unprecedented advances in technology bring both challenges and opportunities to the shipping industry, as Dr Grahaeme Henderson, Vice President, Shipping & Maritime, Shell, and Adjunct Professor, Southampton Marine and Maritime Institute (SMMI) explains.

Climate change is having a significant impact on our oceans. If emissions continue on their current trend, sea levels could continue to rise by as much as two metres by the end of this century (according to the US National Oceanic and Atmospheric Administration). This could have catastrophic results for the estimated 150 million or more people that are currently living on land that could either be submerged or exposed to chronic flooding by 2100.

At the same time, the world is seeing an unprecedented rise in the demand for energy, goods and products, driven by a global population growing by 200,000 people a day. Transportation by sea of the increasing amount of goods and energy the world demands means that, according to the International Maritime Organisation, shipping currently accounts for three per cent of the world’s total greenhouse gas emissions. If unchecked, this will continue to increase significantly. The question is how do we economically ship more goods and energy whilst lowering the environmental impact?

The barriers to change

At the moment, there are very few business drivers pushing the shipping industry to improve its environmental performance. The low oil price has further reduced financial incentives to reduce fuel use, slowing the drive for efficiency. High freight rates mean that new ships are in demand from owners and yards tend to build standard designs, which are understandably optimised for efficiency of production through the shipyards rather than efficiency in operation and environmental performance. Another “split incentive” lies between the owner and the charterer. As the charterer pays for the fuel, the owner of the vessel may not be inclined to invest in energy efficient technology.

In terms of regulations, the IMO have set the Energy Efficiency Design Index, the EEDI, which sets targets for efficiency improvements in the design of new vessels. This global regulation is a first of its kind and a good first step, but not stringent enough.

Shell’s response

In 2012, Shell began a programme to make our shipping operations more efficient. This began with a forensic analysis of over 105 activities that makes up a ship’s journey from the loading to the discharge of a cargo in order to deliver continuous improvement. We minimised durations at berth in terminals, ports and refineries. By reducing loading and discharging time by 13 per cent we have saved around half a day per journey since the programme started, optimising our vessel requirement. It also means that ships burn less fuel in port.

In transit, we have reduced the fuel consumption of our managed fleet by implementing web-based route optimisation tools based on weather conditions, optimising our propeller and hull cleaning cycles and by applying advanced hull coatings.

These and other measures have already led to around a five per cent reduction in fuel consumption and a reduction of CO2 emissions of over one million tonnes.

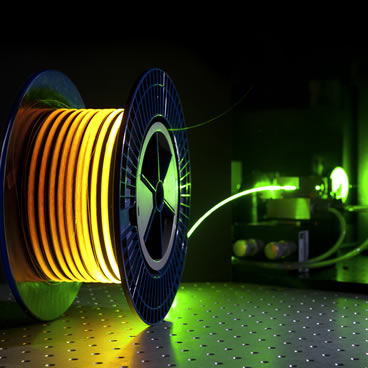

To be really efficient, we need to open up the flow of data enabling us to optimise our operations in real time. “Big data” is an area of particular expertise available in Shell through our partnership with Ferrari. We are working on innovative technologies for our ships, harnessing and analysing the large quantities of data, with resulting optimisation of ship’s operations in real time.

We are also keen to support the speed of development of the new technologies that we believe show real promise in reducing environmental impact such as air lubrication – a blanket of bubbles under the ship’s hull to reduce friction – giving further fuel savings of more than five per cent. This is a prime example of collaboration between ship owners, technology providers, charterers and shipyards.

The need for collaboration

For me, innovation is the most important factor in ensuring that we address the challenges ahead. This is about more than new technology, it’s about new ways of doing business. Technology, although very important, will not be enough on its own to address the challenge. A much more collaborative business model is also needed to align agendas to make the shipping industry a truly efficient, joined-up operation. We need to work with the shipyards to create efficient designs, re-setting the emphasis to operational performance.

We have seen collaboration work in our industry, for example in the area of safety. We can also see how other industries use collaboration to meet ongoing challenges. A strong example is the pharmaceutical industry with individual companies collaborating by sharing big data in an effort to cure cancer. I believe that, if they can do it, so can we.