Hartley News Online Your alumni and supporter magazine

Ben Ainslie, supported by a team of Southampton alumni and other experts, has the America’s Cup and a place in history in his sights.

It has taken over 160 years, but if Sir Ben Ainslie has his way, the America’s Cup could finally be coming home. The Cup is the oldest international trophy in sport, created when the Royal Yacht Squadron organised a race around the Isle of Wight in 1851. Yet despite this heritage, and gallingly for racing enthusiasts and patriots alike, a Great British team has never won it. The fact clearly rankled with Ben, who, within three months of his success with Oracle Team USA in the 2013 America’s Cup, had secured £25m of funding and was gathering a team of experts, including Southampton alumni, to launch his own challenge. In June 2014, BAR (Ben Ainslie Racing, now Land Rover BAR) was officially launched.

America’s Cup sailing is as far removed from Swallows and Amazons and wooden dinghies as it is possible to imagine. For starters, the boats now “fly,” lifted out of the water on hydrofoil daggerboards, which reduce the drag of the hull and help reach speeds of 40 mph. They are also state-of-the-art machines, designed, engineered and assembled by some of the sporting world’s greatest talent, with the benefit of significant funding – the BAR prototype boat is itself worth £1m.

Engineering and design input

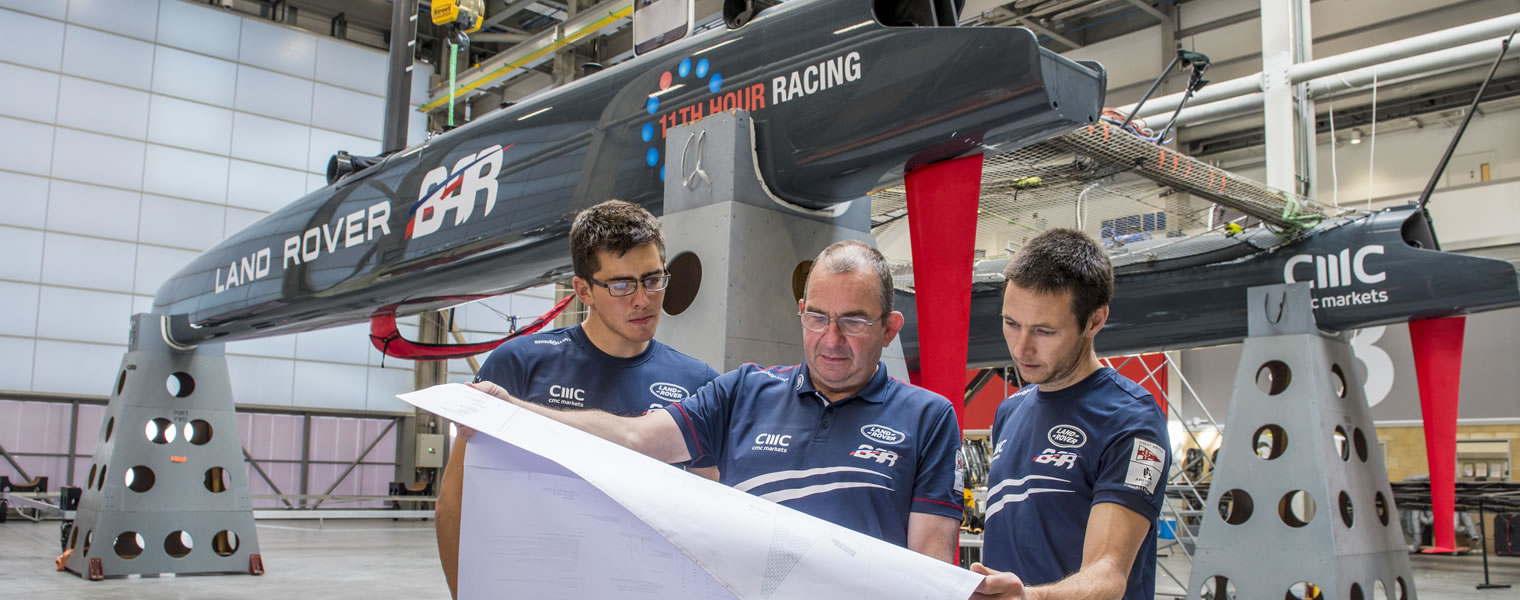

The event is as much about the skills of the engineering and design team as the sailors, in much the same way as Formula 1 car racing. The design and engineering team work hand in hand with the sailors in a symbiotic relationship.

“You have to be strong in all areas. You can’t win having one without the other,” says Simon Schofield, (Ship Science, 2000) design manager and one of five Southampton alumni working in the technical team.

Mark McCafferty, (Ship Science, 1999) engineering manager agrees, highlighting how closely the two work together: “We work as a unit. We have a weekly design meeting where we tell the sailors what we are up to, and there is a debrief every day after sailing. We get feedback on any tests done that day, and what they felt. Working on the cutting edge with that pace of turnaround is exciting. You get feedback very quickly, whereas in industry you are more remote.”

Simulation skills

A key part of the feedback process lies in a sophisticated 3D sailing simulator, a concept adapted from Formula 1. Work on the simulator is headed up by Dr James Roche, (Ship Science, 2006, EngD Aerodynamics and Race Simulation, 2011) whose previous successes, while at Southampton, included designing the skeleton sled that took Amy Williams to Gold at the 2010 Winter Olympics in Vancouver.

“This is the first time that America’s Cup teams have used simulation, and we don’t know of anyone else further along than us. One of the benefits is that we can evaluate different designs in just a couple of minutes. The challenge lies in making sure that the models that we create on a computer match the real world in terms of how the boat will perform,” says James.

In the build-up to the America’s Cup 2017, there are a number of races (collectively the America’s Cup World Series) to be held around the world, which started in Portsmouth in July 2015. Sophisticated television coverage has made the Cup much more of a spectator sport and tickets for the Portsmouth event sold out within days. To enhance the spectator experience, the teams now sail closer to the shore, around a shorter course. As a result, says Andy Claughton (Ship Science, 1975), chief technology officer, “the process becomes a bit more random and an element of luck comes into it. Television coverage has meant that if a race is due to start at 2pm, it will start then even if the conditions aren’t quite right. There’s no question of waiting for two-three hours until the wind has settled and the racecourse is fairer.”

This is again where the simulator comes into its own – all manner of conditions can be simulated, and practice can occur even if the conditions are too extreme for taking the boat out.

University ties

Over one fifth of the BAR design team studied ship science at Southampton, with Benjamin Vernieres (MSc Ship Science and Computational Fluid Dynamics, 2005) working alongside Andy, James, Simon and Mark. The course, says Andy, is unique in the UK.

“It provides access to some fantastic facilities, like the wind tunnel, and the towing tank, where you can get your hands dirty supervised by people who have actually done the job. One of the real strengths of the University is its work in technical sports. They have really moved on the business of designing hardware for professional athletes.

I can’t sing the praises of the University highly enough. They have made every effort to stay abreast of what is going on in industry. In the wider world, including other America’s Cup teams, there is great demand for ship science graduates, because they have a grasp on engineering, fluid dynamics, and aerodynamics,

he continues.

It is not just on the design team that experience gained at Southampton is appreciated. Sailing team members Paul Campbell-James (Ship Science, 2004) and Bleddyn Mon (MEng Mechanical Engineering, 2015) are evidence of the development of a new breed of technically highly-qualified sailor.

Legacy plans

Since its launch in June 2014, BAR has secured over 70 per cent of its £80m funding goal, part of which has been spent on building a 74,000 square foot headquarters in Portsmouth. The focus for the next two years is on winning the Cup, but BAR has been created as a sustainable business with long-term plans and ambitions. That starts with hosting the next America’s Cup in Portsmouth, should they be successful in 2017. It is also hoped that the technological knowhow gained will be put to good effect.

“Going forward, quite a lot of the technology that we use could go into the wind propulsion of ships. Within the EU Horizon 2020 programme*, there is a tranche of funding to support more efficient transport, such as using wind power to drive commercial ships. I hope our work here could feed into that in the future,” explains Andy.

The venue itself could also help promote a meeting of minds. Not only is it an excellent centre for running corporate conferences, meetings and events, hosting an America’s Cup would inevitably generate a high technology footfall through the area. Given the opportunities for technology transfer that already exist between land, sea, and air transport, this cross-fertilisation could benefit many different industries. Having Land Rover as its exclusive innovation partner, and Martin Whitmarsh, formerly of McClaren as CEO, is testament to this cross-fertilisation.

Right now, however, the name of the game is winning the Cup, and the team are confident.

“We have good financial support, one of the world’s best sailors fronting the team up, and an opportunity to do it with no obstacles. There is no excuse to lose here. That’s both encouraging and daunting in equal measures,” concludes Andy.

For more information about the team, visit www.landroverbar.com

* the largest ever EU Research and Innovation programme, with nearly €80bn of funding available over seven years, up to 2020.