Hartley News Online Your alumni and supporter magazine

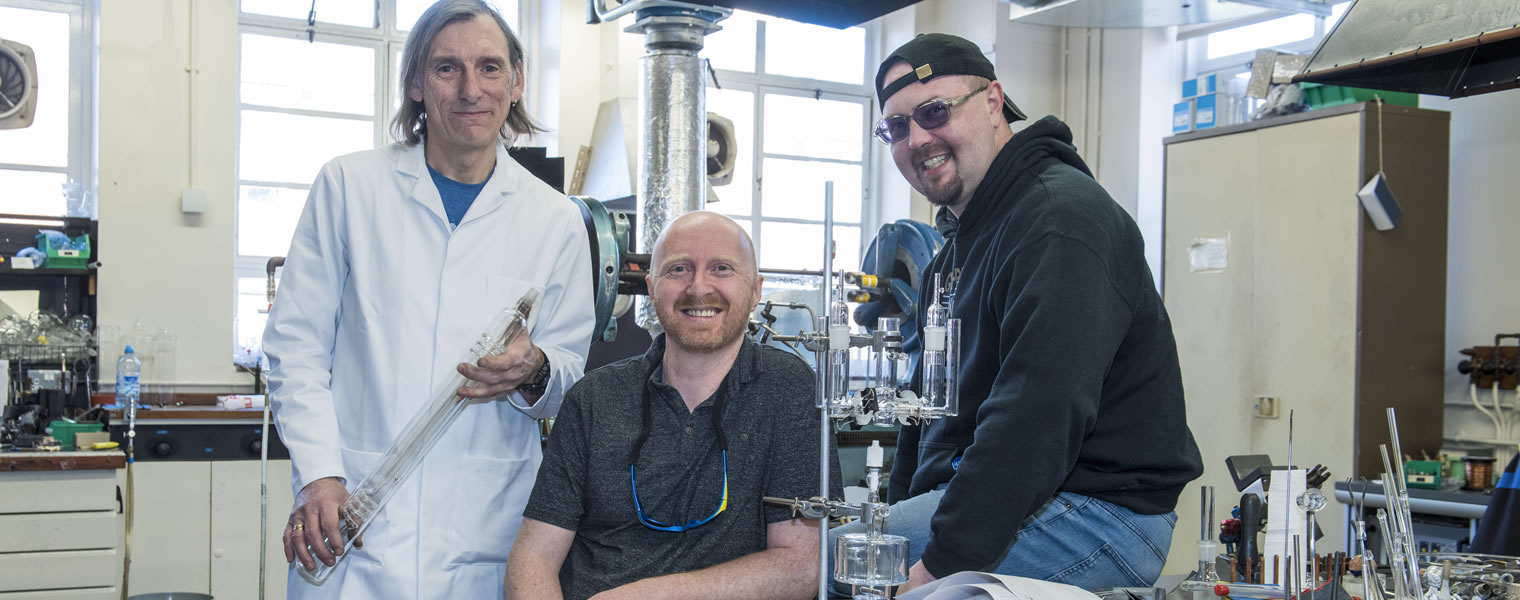

Southampton Connects Staff meets Lee Mulholland (LM), Przemyslaw Tryc (PT) and Paul Frampton (PF) from the University’s Scientific Glassblowing Service and learns how their work sometimes leads to great discoveries.

What does the glassblowing service do?

LM: We design, manufacture and repair bespoke glassware for any branch of science, but mainly chemistry.

Why does the University have its own glassblowing service?

LM: Having a workshop onsite is a huge time and money saver for the University. Design consultations are so much easier when they can be done face to face and ideas can be given to the customer and designs often evolve once we start talking. Also, often one piece of broken glass can stop an experiment in its tracks and getting it repaired quickly is essential.

How long have you each been doing this type of work?

LM: Myself and Przemyslaw have both been working in scientific glassblowing for about 15 years while Paul has 40 years’ experience.

What sort of training do you need to do this job?

PF: It is very much on-the-job training, as there are no specific training facilities for scientific glassblowing. There is an exam syllabus provided by the British Society of Scientific Glassblowers that Lee and Paul have completed, but it is generally accepted to be a seven- to 10-year apprenticeship.

What do you most enjoy about your work?

PT: Everything.

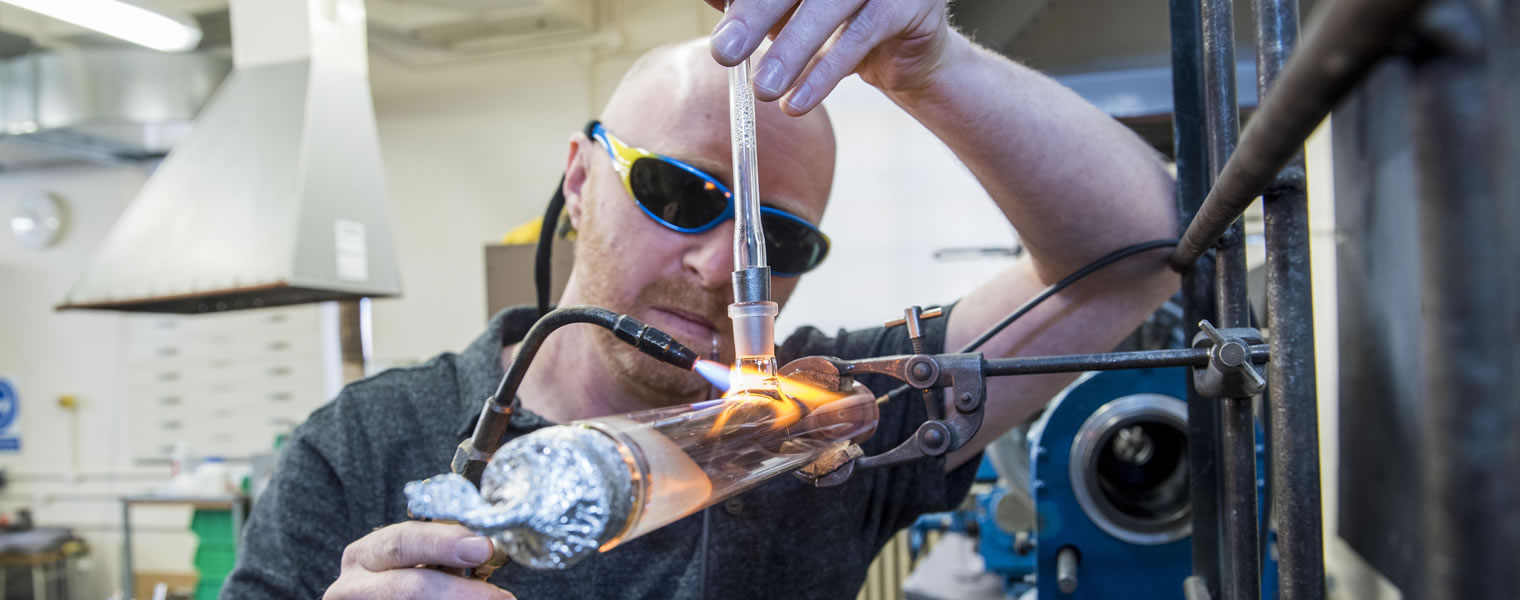

Glass is a wonderful medium to work with, if you can handle it properly of course. It’s about making things out of nothing: creating something that didn’t exist before. You can start with just a simple glass tube and finish with a great, sophisticated piece of glass that looks absolutely fantastic.

Of course, mostly we repair or modify existing items, but sometimes we are creating absolutely new things that may lead to great discoveries. I like to think that I am a small wheel in machine that changes the world. Shaping glass, making it behave as you want it… it’s just awesome. And we play with fire all day long.

What are some of the challenges you face?

PT: When I am consulting in the design process, it’s sometimes challenging to find a common ground with a client and persuade them to modify their design without changing the purpose of the glass. It’s all about understanding and making clients happy, sometimes even providing them with something they didn’t know they wanted.

How do you make sure the glass is suitable for research purposes?

LM: Most laboratory glass is made from Pyrex so that it can cope with thermal shocks better. I wouldn’t say it is ‘extra strong’ but we obviously have to make sure that each piece is strong enough to cope with what it will be put through. This could mean withstanding vacuum or pressure, so the thickness of the glass will be calculated accordingly. Sometimes the complexity of the designs makes them very fragile indeed.

What makes a good glassblower?

PT: A certain level of dexterity, that’s for sure. Determination and patience is needed, especially at the beginning, to pass the first two years of training. Most people resign before they’ve acquired the basic skills and before they are able to notice any progress.

It’s also helpful to have some knowledge about how things work: a basic understanding chemistry and physics is useful. Problem solving in design and out-of-the-box thinking are also handy skills to have, but I think most of it comes from practical experience.

Which departments, faculties and academic units use your services?

LM: We have done work for most of the scientific departments across the University over the years, but mainly Chemistry, Physics, Engineering, the Optoelectronics Research Centre (ORC), and the National Oceanography Centre Southampton (NOCS).

Sir Christopher recently announced a new strategy. He mentioned the principles of quality, internationalisation, collegiality and sustainability. How do you feel you fit in with all of this?

LM: I think we fit in with all of these.

We do the highest quality work for customers all over the world. We are closely connected to the global community of scientific glassblowers and provide a valuable service that enables quality research to be carried out in a sustainable manner.

Have you won any awards?

PT: The British Society of Scientific Glassblowers has a symposium every year and runs competitions for scientific glassblowers. Over the years, we have won seven national competitions.

What are you most proud of?

LM : That’s a hard one! The glass baby we made for Professor David Phillips from Chemistry was probably the most memorable.

I am most proud of a ‘high throughput electrochemistry cell’ that I made for Professor Brian Hayden’s Advanced Materials Facility, also in Chemistry. I won a national glassblowing competition with it. Even though I made it six years ago, I still sometimes wonder how I made it so perfectly!

If you weren’t glassblowing objects for a university what would you like to create using glass?

LM: I have a torch set up at a friend’s workshop and I really enjoy making glass marbles in my spare time.

What’s the difference between scientific glassblowing and normal glassblowing?

LM: The main difference is that we heat the glass using flames from torches rather than a furnace and we use Pyrex rather than soda glass.

Have the requirements for glassblowing changed over the years?

PF: Not really. The materials and equipment are mostly the same. I would say that there is a tendency for things to be getting smaller as people want to deal with smaller volumes of expensive products.

Do you do work for other universities and/or for industry?

LM: Yes we work for many other universities as they continue to lose their glassblowing services and our industrial customer base is growing on a monthly basis.

We’re really keen that anyone from across the University who needs some glassware contacts us first; you will find our services much cheaper and more convenient than external suppliers.

For more information, visit www.southampton.ac.uk/chemistry/business_partnership/services/glassblowing.page