Hartley News Online Your alumni and supporter magazine

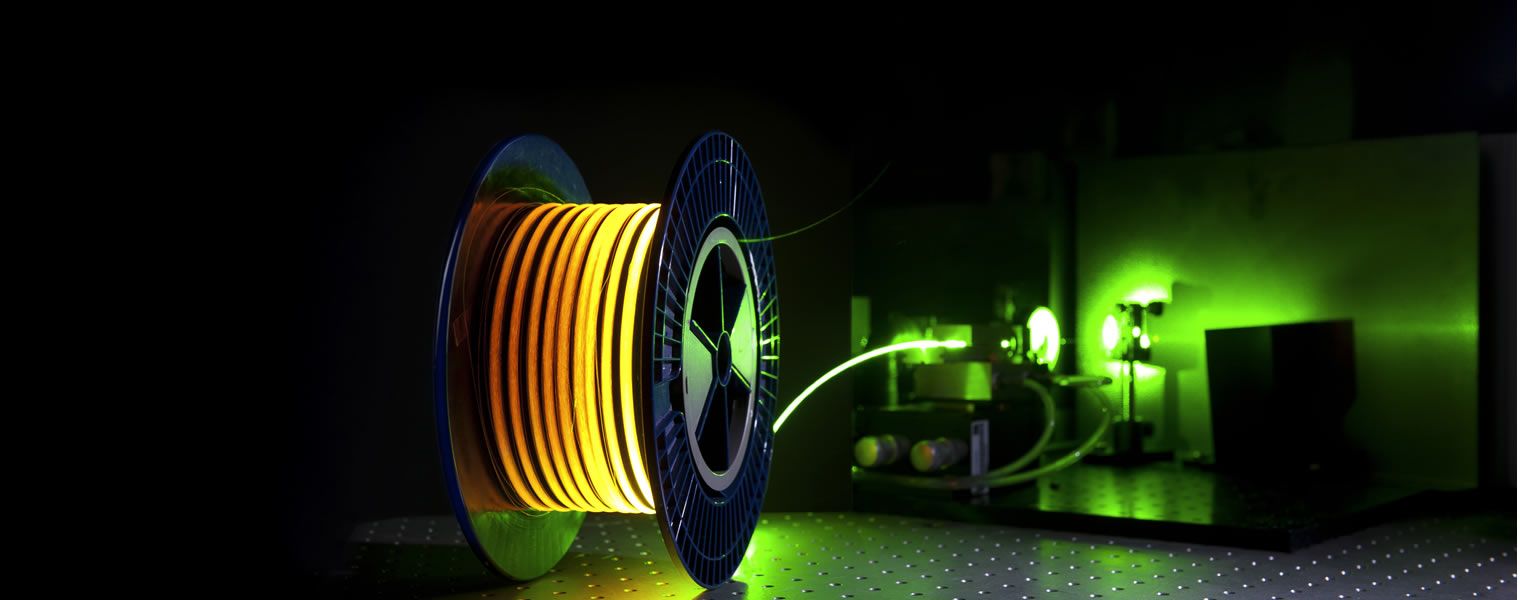

Photonics has a huge impact on our day-to-day lives, from navigating airlines to powering the internet. It is a crucial technology for the economy; around 30,000 jobs and 3,000 companies are dependent on photonics in the UK alone. To mark the International Year of Light, Southampton Connects asks two leading researchers in photonics what Southampton is doing to drive the field forward.

Professor Sir David Payne (BSc Electrical Engineering, 1966; PhD Electronics and Computer Science, 1977), Director of the Optoelectronics Research Centre (ORC) at the University of Southampton:

Here at the ORC, we have been at the forefront of photonics for the past 40 years. Our research connects the planet: the global internet relies on our invention of erbium doped amplifiers that boost optical signals, allowing fast telecommunications. When you travel by plane, you are being navigated by our optical fibres. We are incredibly fortunate here at Southampton in that we can go all the way from electrons to enterprise; from photons to production. In other words, we can make new fibres, emitters and circuits, develop a new device based on those components, test this in a system and start a company. Very few universities have this capability to go from end to end. This is thanks to our magnificent clean room complex, which is one of the best in the world.

Ten companies have spun out of the ORC so far, all of which are manufacturing businesses, and we are very proud of that. Our drive to innovate and capitalise on our research means there are more special fibre drawing plants in Southampton than any other city worldwide.

So what’s next? If the internet continues to grow at the current rate – 30 to 40 per cent each year – it will soon reach its limit. To address this we are working on a new field, silicon photonics, that marries the parallel technologies of electronics and optics to get the best of both worlds. Optics has a major part to play in the ‘internet of things’ of the future, and is paving the way for a new generation of sensors with unforeseen capabilities. Imagine a sensor that could run hundreds of kilometres along a railway track, giving real-time information on a train’s location, speed and the condition of its wheels; this is just one of the new sensors we are developing here at the ORC.

My strategy and research direction has always been to notice what it is that is different in a new invention. Thanks to fibre lasers, which we pioneered here, for the first time we can combine many thousands of individual lasers together to create an energy density that exceeds that on the sun. The energy density this produces inside a vacuum could be high enough to rip it apart and create something: exactly as is believed to have happened in the big bang – a crazy idea that just illustrates the potential of photonics. Practical applications could include making the next accelerator for CERN or creating a capability to shoot space debris out of the sky.

The International Year of Light, within what is the Century of Light, is a huge opportunity to raise the profile of photonics, especially to young people. We need bright young people to take these ideas forward and bring into reality a new generation of technology that was unimagined a decade ago.

Dr Steve Norman (BSc Hons, 1972; PhD Optical Fibres for Communications, 1981), Technical Consultant and Director, SPI Lasers UK Ltd:

SPI Lasers’ products, all of which are based on fundamental inventions from the ORC, are used to make a broad range of consumer products that affect nearly everyone in society. Examples include medical stents for alleviating heart attacks, mobile phones, laptops, solar cells, batteries, automotive components and large sheet metal products. SPI Lasers manufactures in the UK, employs 350 staff in the UK (around 250 in the Southampton area) and exports 95 per cent of its products, with over 35 per cent going to China.

Success in highly technological industries derives from the ability to take groundbreaking research inventions, to carry them through to product design and development, and on to full commercialisation. The UK is justifiably renowned for its creativity and its ability to innovate, and the University’s ORC has excelled in the photonics research field since long before the word ‘photonics’ was coined. Moreover, in this field, the ORC’s track record in downstream commercialisation of major technological innovations is among the best in class. For example, the development of optical fibre manufacturing technologies in the 1970s, the invention of the erbium-doped fibre amplifier (EDFA) in the late 1980s, the use of optical fibres as high-performance sensors, and importantly the invention of the optical fibre laser in the 1990s were all breakthrough inventions that have evolved into multi-billion-dollar markets in which Southampton-linked companies are important players.

What characterises these successful developments? Firstly, good alignment between the research team’s interests and the business strategy of the industrial partner is essential; this can be fostered either through staff secondment, or through tightly linked research collaboration in a relevant field. Secondly, industrial foresight and investment in early-stage technology-watch activities can enable rapid commencement of first-stage (high-risk) embryonic product development. And lastly, entrepreneurial risk-taking attitudes, coupled with an enthusiasm to take research to real product, are essential to drive innovative technologies.

In all these respects, SPI Lasers is proud to have taken many of the ORC’s innovations to market over the 15 years since our formation as a ‘spin-out’ from the ORC. We have very successfully reinforced our technological linkages to the ORC by establishing and co-locating an advanced R&D group at the University, with SPI and ORC staff working together. We have ongoing interactions and exchanges on joint projects and can frequently support researchers with commercial-off-the-shelf (COTS) devices to facilitate their research. The critical element of trust exists between academic researchers ready to put industry challenges at the centre of their work, and industrial developers willing and capable of absorbing innovative ideas from academic research.

With its major impact on society over the last 40 years, Southampton can be very proud that it has such a world-class centre. It is well placed to be a catalyst and technology driver for the future growth of UK photonics enabled manufacturing industry.

For more information, visit www.southampton.ac.uk/orc